This style is Tongsheng’s smallest blow moulding machine, It’s character is small size, high speed, stable and energy-saving. It can match the auto bottle mouth deflashing device, rotary bottle mouth cutting device, conveyor belt and automatic crusher system. Single mould head, double mould heads, three mould heads, four mould heads and six mould heads to be selected, the daily output(24 hours) reaches approximately from 20,000 to 120,000, it can produce from 0.01 to 1.8L plastic hollow products. Suitable for production of HDPE PETG PP PVC PC ABS as raw material of medicine bottles, Chewing gum bottle, Cosmetics bottles, such as hollow container products, products of the largest volume of 1.8 liters.

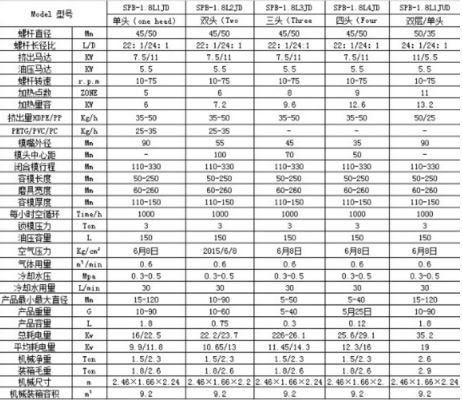

SPB-1.8L Series Blow Moulding Machine Parameter List

Tongsheng Blow Moulding Machine Feature Control System Choose the European and world-famous brand, the man-machine interface display. Mechanical movement real-time monitor display. Freely 100 points setting parison container wall-thickness control. Precision of the analog reach upto 16 bytes. Display fully-automatic cycle time. Display real-time failure alarm information and diagnosis. Alarms display for adjustments of heating, temperature-value, pre-heat, high-low temperature... Multi-function safety interlocks. Freely Parameters setting on panel buttons directly. Mould Die Head System The minimized centre distance of multi-runner die-head design provide higher flexibility of the mold with more cavities. Adopt centre feeding flow-distribution and core-type complementary runner give container wall-thickness more even&faster color change. Extrusion system Frequency converter for motor driver. Enhance screw-end cooling zone water-jacket design provides efficient material feeding, higher extrusion capacity and stable quality control. High precision temperature PLC control. Multi-purposes design of screw provides not only uniform plasticization but also high production. Hydraulic System We co-operate with the world-brand high standard hydraulic manufacturers, Vickers, Bosch\Rexroth, Yuken and Moog providing us the most efficient pumps, proportional valves, directional valves, accumulators and filters in addition to our professional circuits-design, fast response, high speed, stable, energy saving, low noise, long working life and both environmental&user-friendly from our machines are gained. Air Supply System Thanks to our experience for many years in this field and the expertise suppliers of FESTO and SMC from Germany and Japan, we adopt and produce a series of high quality&reliable air-circulation system including the blowing technology, clearance airing and airing drying system to our machines. Clamping system Clamping cylinder at mold platen centre giving evenly-pressure loading and good quality production hence longer mold life is also benefited.